The main characteristics of three-dimensional ribbed tubes are as follows:

1. High heat exchange efficiency, compact structure, and more heating surfaces can be arranged in the same space to reduce exhaust temperature and achieve energy conservation.

2. The metal wall temperature can be adjusted by adjusting the number and structure of ribs to avoid acid dew points.

3. While ensuring heat exchange capacity, the designed flue gas flow rate can be appropriately reduced to reduce wear and prolong service life.

4. Have a certain degree of self cleaning ability.

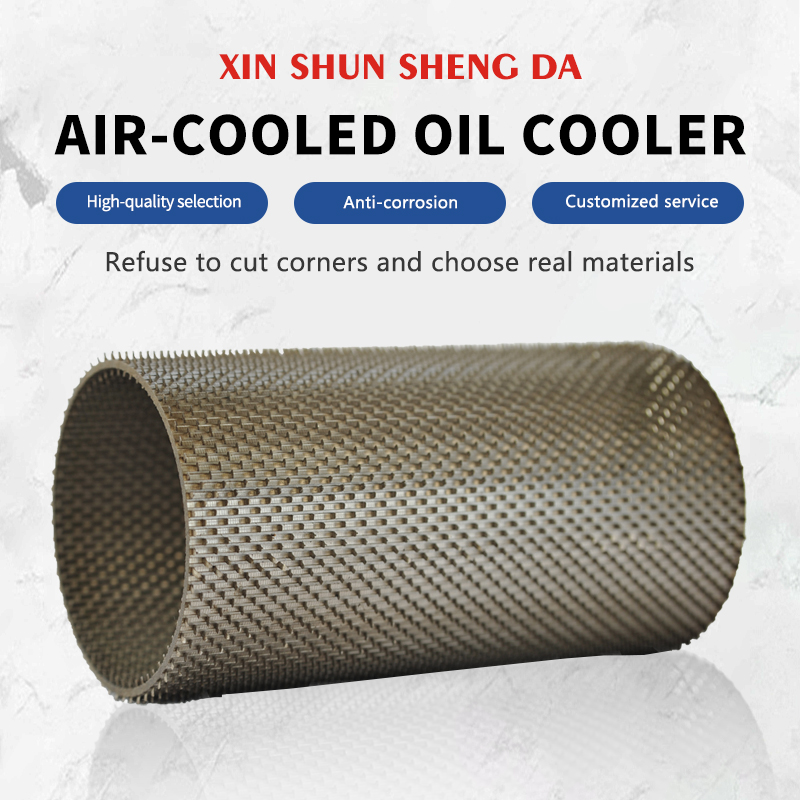

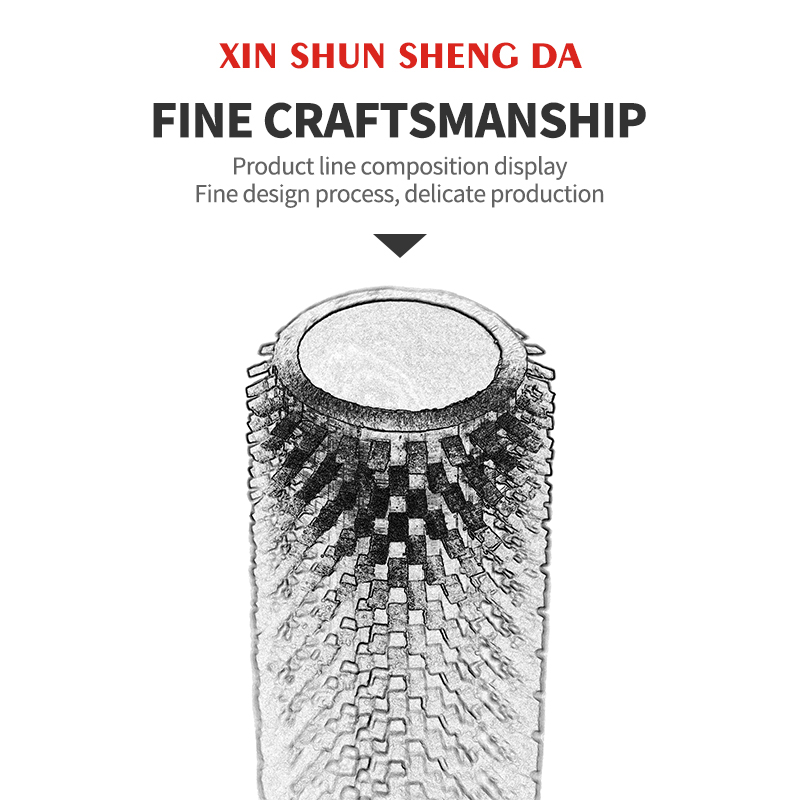

The three-dimensional inner and outer ribbed tubes are processed by cutting the inner and outer walls of metal tubes. The rib surface is a combination of a curved surface and a flat surface, known as the "three-dimensional" ribbed technology. This is not only a new processing technology, but also a technology to strengthen heat transfer, especially the heat transfer inside the tube. Other technologies are difficult to achieve, and this form of heat exchange tube has a heat transfer effect 2.5 to 6 times higher than ordinary smooth tubes. Three dimensional finned tubes are a new generation of non continuous enhanced heat transfer tubes composed of fins. The erosion of fins caused by three-dimensional fluid flow is better than that of two-dimensional fluid flow, and they have stronger anti fouling and heat transfer capabilities. The three-dimensional fin can be seen as a needle punched tube with both internal and external needles, or as an h-shaped finned tube with discontinuous fins, but it has stronger heat transfer ability, ash accumulation resistance, and wear resistance; integrated processing without contact thermal resistance; by adjusting the number, height, and arrangement of ribs, the temperature of the pipe wall can be adjusted, which is beneficial for reducing the risk of low-temperature corrosion; it can increase the spacing between heat exchange tubes appropriately, which is beneficial for ash cleaning and maintenance and tube replacement; the simultaneous heat transfer enhancement inside and outside the tube makes the heat exchanger more efficient and compact, making it an efficient heat transfer element with excellent heat transfer performance.

Chongqing xinshun shengda technology co., ltd. Was established on august 26, 2020, with its registered address at no. 5, chuangxin avenue, changzhou street, rongchang district, chongqing, and its legal representative is xia hao. The business scope includes the licensed project: Construction engineering construction. General items: Technical service, technical development, technical consultation, technical exchange, technology transfer and technology promotion; r&d of key technologies for waste heat power generation; sales of gas and liquid separation and purification equipment; energy conservation management services; research and development of efficient energy-saving technologies in the power industry; manufacturing of refrigeration and air conditioning equipment; sales of refrigeration and air conditioning equipment.

An energy-saving and environment-friendly high-tech enterprise developed on the basis of chongqing university 3d energy saving technology development co., ltd., which was established in 1991. Driven by new energy-saving technologies, the company tailors an optimization scheme for the comprehensive utilization of energy for enterprises and provides energy-saving and environment-friendly heat exchange products and technical services for enterprises.

Wang Lei

104555668@qq.com

Disclaimer: This article is reproduced from other media. The purpose of reprinting is to convey more information. It does not mean that this website agrees with its views and is responsible for its authenticity, and does not bear any legal responsibility. All resources on this site are collected on the Internet. The purpose of sharing is for everyone's learning and reference only. If there is copyright or intellectual property infringement, please leave us a message.

©Copyright 2009-2020 Startup Weekly Contact Us SiteMap